Industry leading approach to climate change

We’re unlike any other heavy industry player, with a costed plan to decarbonise our Scope 1 and 2 emissions across our terrestrial Australian iron ore operations, while developing projects and technology to help scale green energy and green hydrogen globally.

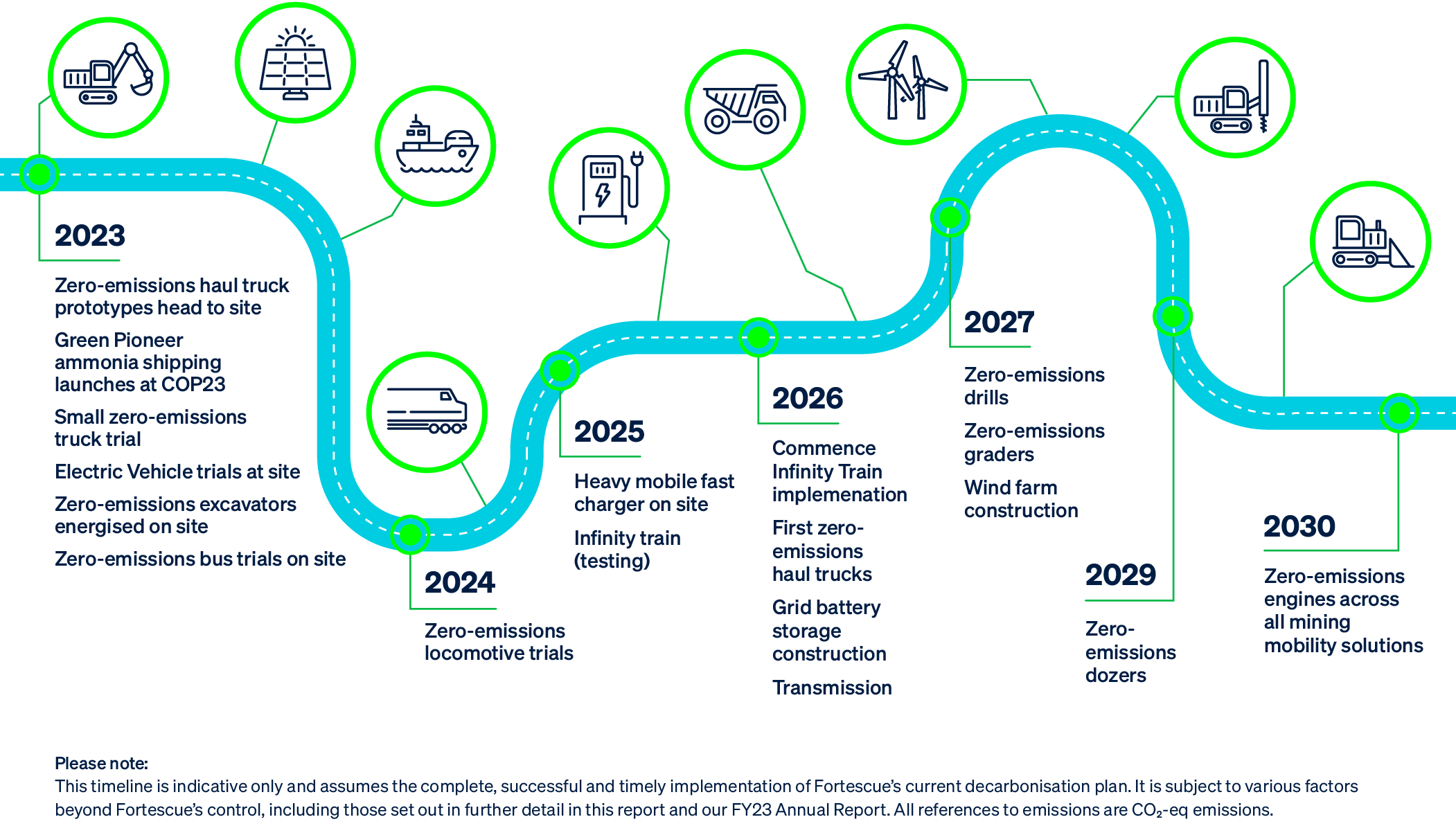

Achieving Real Zero by 2030

We have identified preferred solutions to eliminate approximately 90% of our CO2 equivalent terrestrial emissions associated with our Australian iron operations by 2030. In September 2022, Fortescue committed US$6.2 billion dollars to achieve this plan.

By 2030, decarbonisation will allow us to save over 700 million litres of diesel, and 15 million GJ of gas and avoid 3 million tonnes of CO2 equivalent emissions each year. This will generate significant cost savings for our business – for example in FY23, we spent over US$560 million on diesel and gas. We have already stopped buying voluntary carbon offsets which have been shown to be troubled by extensive concerns about quality and an ability to achieve a real reduction in emissions. Further details on our we are eliminating emissions are outlined in our annual Climate Change Report.

We are working hard to identify and evaluate different technology options to eliminate the final 10% of emissions and remain on track to achieve real zero by 2030.

In our work to move beyond fossil fuels, we are also creating new global opportunities for green iron, green steel, green hydrogen, and green ammonia.

Net zero Scope 3 emissions by 2040

Scope 3 emissions are those emissions that fall within a company’s value chain but are outside its operational control.

By far the largest source of Fortescue's Scope 3 emissions is the steelmaking process, which accounts for 98% of our Scope 3 emissions. Steelmaking generates significant emissions due to its current reliance on coking and thermal coal, however new approaches that use renewable electricity and green hydrogen to produce green steel are under development by Fortescue and other businesses.

Our approach to reducing Scope 3 emissions is to develop projects and technologies with a focus on reducing emissions from iron and steel making and to work with current and prospective customers on the application of the technology and the supply of green hydrogen and ammonia from Fortescue.

We have set the following Scope 3 targets:

- By 2030, enable a reduction in emissions intensity from steelmaking by Fortescue's customers of 7.5%, from FY21 levels

- By 2030, enable a reduction in emissions intensity levels from the shipping of our iron ore by 50%, from FY21 levels

Fortescue is working hard to decarbonise its fleet of eight ore carriers via green ammonia and engaging with the shipping industry to reduce, and eventually eliminate, emissions from shipping.

Our targets align with a 1.50C trajectory as we work towards achieving net zero one decade prior to 2050.

Fortescue publishes details of its Scope 3 emissions in its annual FY23 Climate Change Report. Details of the methodology used to estimate Scope 3 emissions can be found here.

Decarbonisation strategy

Fortescue recognises the urgent, global need for innovation at scale, both to enable heavy industry and to drive large scale, both to enable heavy industry to decarbonise and to drive large-scale generation of green energy and green hydrogen.

Through inhouse scientific teams and with the collaborations and engagement with other companies and academic institutions, we are developing and implementing decarbonisation solutions that can help address our Scope 1, 2 and 3 emissions.

Our climate change strategy focuses on

- Decarbonisation of our iron ore operations

- Decarbonisation of our value chains

- Fortescue Energy

Green power

We are making significant investments in renewable power, battery storage, and transmission links to displace stationary diesel and gas-fired power generation at our sites.

We are delivering our US$700 million Pilbara Energy Connect project, which will integrate the stationary energy facilities across our remote sites in the Pilbara into an efficient, secure and resilient network, enabling us to reduce emissions and incorporate the additional renewable generation necessary to help decarbonise our operations. This includes:

- The 223km high voltage transmission line linking our Solomon Hub with Iron Bridge and Port Hedland, effectively eliminating the need for diesel-fired power generation at Iron Bridge

- Installing a 16MW battery at our Solomon Power Station and a 26MW battery at Iron Bridge to provide network support and power stability

- Connecting the Herb Elliott Port to the PEC to operate on renewable power, reducing almost all of our Scope 2 emissions once implemented

- Receiving renewable power from Alinta Energy via the Chichester Solar Gas Hybrid project.

Fortescue is the future

Being a good global citizen is not separate to our national economic interest. It’s key to it. We sit at the tipping point of global warming and global mindsets - one that will see decarbonisation shift abruptly from a 'nice to have' to essential to our existence.

Dr Andrew Forrest AO

Executive Chairman